A Certified Naturally Grown Farm - Saint Marys, Pennsylvania

What We Grow

Original Hopyard

We got our start with hops in May 2014. Our very good friend Adam Seitz, owner of Penns Mault in Spring Mills, recommended them to us after our high tunnel collapsed in 2012 and we decided to put any idea of a vegetable CSA on the back burner. I read as many books and articles as I could find and watched every YouTube video on the topic I could. In addition, both Adam and I attended the Farmer-Brewer Conference in February of 2012 far north in Hadley, Massachusetts.

After searching extensively, I was recommended by a number of organic hops growers to speak with the folks at Blue Ridge Hops. Blue Ridge Hops is a small family farm, located in Marshall, North Carolina, where spectacular long-range views surround the hops yard. Owners John Wright and Rita Pelczar have been growing USDA Certified Organic hops since 2009. They recommended two hops varieties, Cascade and Nugget, that are both used in a wide variety of beers and have shown great success when grown in an organic system.

Starting small, we ordered 20 Cascade and 10 Nugget rhizomes. Hop rhizomes are small roots that are cut from the main root system of a mature female hop plant. Most growers will plant the rhizomes directly in the fields, however I wanted to give our fellas a jump start and we planted them in pots and let them sprout and mature under 18 hours of fluorescent lights, just as any grower would do starting transplants.

In this our original hopyard, we use a traditional trellis system…

- Black locust poles as they are highly rot resistant since we cannot coat them with any preservatives

- Poles are 24′ long, we bury them 4′

- High tensile 5/16″ wire rope runs from augers buried deep in the ground, up to the end poles and between all the poles

- We run coir (twine made from coconut husk) from the beds where the hops are planted directly up to the wire ropes above

- In the original hopyard, we run one “bine” per plant on the coir. Each bine has 3-4 hops arms growing on it

- We mulch with composted yard waste such as grass clippings and leaves, which we have in abundance

- When rainfall (or lack thereof) hasn’t provided adequate irrigation to the hops naturally, we supplement it with a drip irrigation system

Expanded Hopyard

Hops plants, on average, take anywhere from 3-5 years to become fully mature. That means the first couple years the hops are growing, we are just catching a glimpse of how many pounds of hops we’ll be able to harvest per bine. In our harvest from September 2014, we harvested approximately 4 pounds “fresh” (not dried) between the Cascade and Nugget varieties. Additionally, it only took two of us (myself and my Dad) about 45 minutes to do so.

By contrast, for our harvest in August 2015, it took 6-8 of us almost a full 8 hours total spread out over 2 days to yield approximately 35 pounds “fresh” (23 pounds Cascade, 12 pounds Nugget) which dried down to about 5 pounds of Cascade and 2.6 pounds of the Nugget.

The new hopyard is located in the Northwest corner of our property and encompasses almost an acre. There are 5 rows, each with 9 poles and 8 beds in each row. Each row will house a different hop variety with 80 plantings in that row, for a grand total of 400 hops plants. Our varieties will include:

- Cascade

- Nugget

- Horizon

- Brewer’s Gold

- Vanguard

The overall design of the yard remains the same, however we will be trellising using what’s called a “V-trellis” system. Instead of only 1 bine per planting and growing it directly vertical to the overhead cable within the row, we will be growing 2 bines per planting and sending one diagonally to an overhead cable in one alley and the other diagonally to the alley on the other side of the row. It will look similar to this image.

The advantages of this system include increased production capacity, more efficient harvesting techniques with larger equipment, increased airflow and exposure to sunlight in the hopyard and a more efficient irrigation and weeding infrastructure.

Barley & Small Grains

“If you’re going to grow one beer ingredient, why not two…or more?!”

As mentioned earlier, one reason we explored hops…other than the fact we love beer and our hometown brewery…was that it is a perennial plant not requiring as much daily attention as say vegetables. Because we aren’t currently able to work the Farm on a daily basis living some 90 minutes away in State College, we needed to find some interim solutions until we move back to the area.

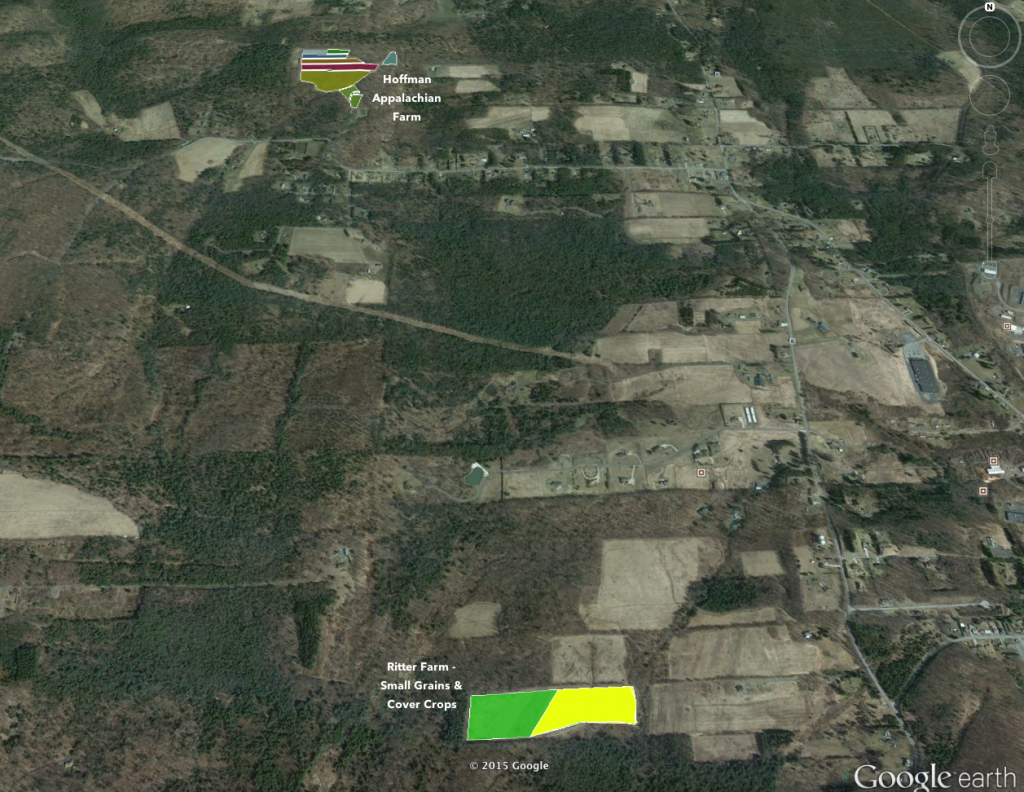

Hops seemed like a good choice for that reason and many others. Then of course, when your co-worker…now the proud proprietor of a malt house…says, “maybe you should grow barley?!”, you of course listen to him…again. With the help of a good local friend of the family Joe Schroeder, who just happened to have a 50hp+ tractor he’d been dying to put to real farming use, a 7 acre parcel wedged in between the original and expanded hopyards was plowed and disced. We then turned to our old friend Ted Weisner to drill the barley seed. These steps were both completed through the early to mid part of September.

We planted our barley, a “Winter” variety, at this point in the season as it would allow it to become established before Winter set in. It would then, in theory, lie insulated under a good layer of snow (not ice hopefully as that’ll kill it!) and get a head start on the weeds when Spring arrives and would then allow for a Summer harvest. Now the barley in this field cannot be one of our Certified Naturally Grown plots for another three years as it’s in a “transitional” status. Meaning, previously it was planted with a conventional seed/crop (clover) and according to the organic standards upon which our CNG status is based, we cannot not claim that field in our certified acreage until after three years have passed.

We will however manage it going forward according to the CNG standards so that in 2018 the crops we harvest will in fact fall under our certificate. Another key aspect of the process is that we will be rotating between small grains such as barley, rye and spelt along with cover crops. The cover crops will not be grown for the sake of harvesting but rather to continue building the organic matter in the soil, reducing the need for additional organically approved fertilizers, knocking back the weeds, prevent soil erosion and conserve soil moisture among other benefits.

We also are already working at a nearby farm to begin preparing their fields that have sat fallow for more than forty years and to include them in our rotation schedules. This will give us greater flexibility in the type of crops we can grow within one season, allow for a proper rotation between cash and cover crops and simply get more local land back into agricultural production.

The Future

What does the future hold…well, what we make of it mostly!

Working on the timeline that we will be moving back home to Saint Marys sometime in 2018 after our youngest is off to college, we will then have the time and flexibility to dive back into some of the projects we originally considered: a four-season vegetable CSA and orchard. There are other specialty crops such as mushrooms that may also be possible. We want to diversify as much as possible without over-extending ourselves. Our mission will always be to remain a small, family-owned farm worked primarily by members of our immediate and extended family, along with other members of the communities we serve.

The photos below highlight our current plans. While we can’t predict the future, we can certainly help shape it.