A Certified Naturally Grown Farm - Saint Marys, Pennsylvania

Spring 2025 | Too Much Rain, Too Little Sun

Posted on June 9, 2025 by Joshua

Early Start

Most “Farm days” start either with an evening drive up to Saint Marys from Montoursville the night before a work day, or early the morning of. This weekend’s was an “early of”, arriving at the Farm around 7am.

As I always do, I’d looked at the weather forecast every day, and multiple times per day, watching the chance of rain bump up on Sunday (the day I’d chosen based on initial weather forecasts) and the chance of rain Saturday decrease, the day I passed on because of it. As I stood out in the beautiful weather of Saturday in Montoursville, in the back of my mind all I could hear was, “you’ll pay for this tomorrow”. And I did.

The day started out quite nice…a bit cool and overcast, but no rain. It’s not ideal but often giving my schedule conflicting with the weather I have little choice, but I sprayed our organic fungicides, insecticides, and started foliar and soil drenches of fertilizer.

Keeps Me Up At Night

There’s no way to sugar coat it, about half of the bines are struggling this Spring and I’m not expecting a good harvest. I’m attributing it primarily to the unusually cold and wet May we had, which is often when the bines are establishing themselves on the coir once trained. Obviously rain they need, however the heat and warmth of sun is also necessary and that was in short supply most of May. The only other possible contributor was a switch in nitrogen source in the Fall putting them to bed. We lost our source of composted horse manure and needed to switch over to mushroom compost.

Some bines are so weak, they’re “un-training” themselves from the coir. It’s both scary and sad as I’ve never seen them like this before. The odd thing is, we’ll have 3-4 bines that look right on schedule, then 3-4 next in line that look abysmal, then another group of healthy, back to unhealthy, etc. Same processes and materials were used consistently through the yard so I’m at a little bit of a loss.

“Do What You Can…”

“Do what you can, with what you have, where you are.”

Theodore Roosevelt

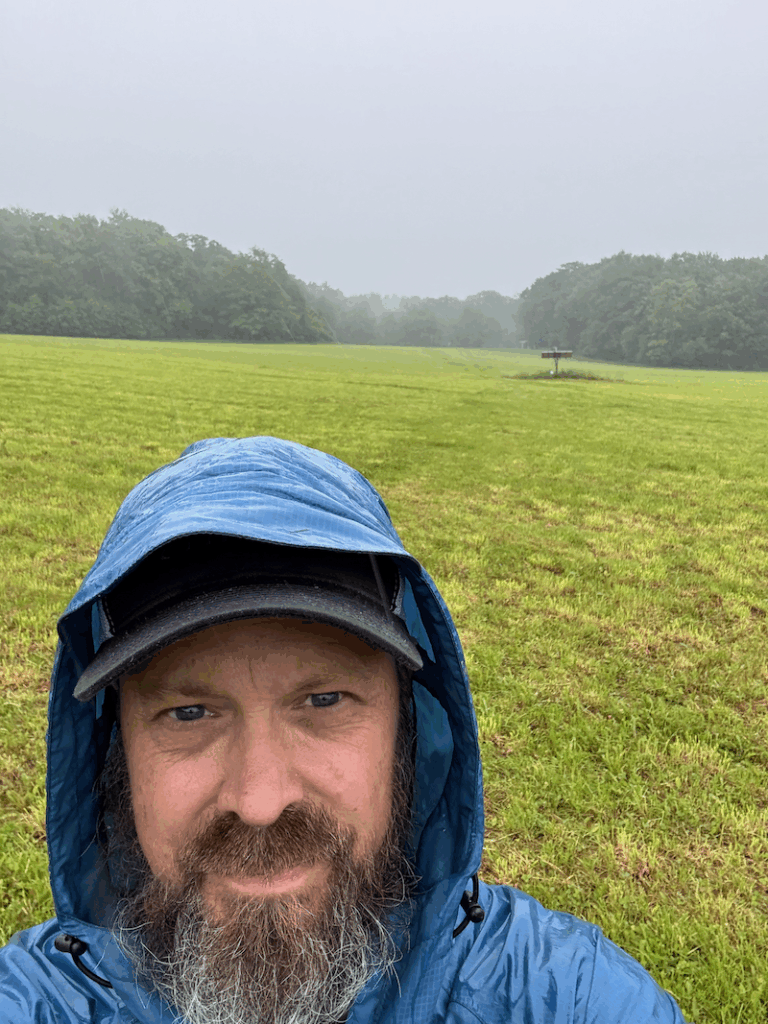

And then the rain set in just before noon to add to my demeanor. There are many things Farmers are NOT supposed to do with wet soils, let alone when it’s pouring rain. One of them is getting the tractor out in the fields as it creates ruts and compacts soils. But technically I wasn’t in either of the hop yards, I was mowing the old Keystone Road that is part of our driveway and then moving an implement from near the barn up to where we park the tractor. Still…it was pouring and not ideal.

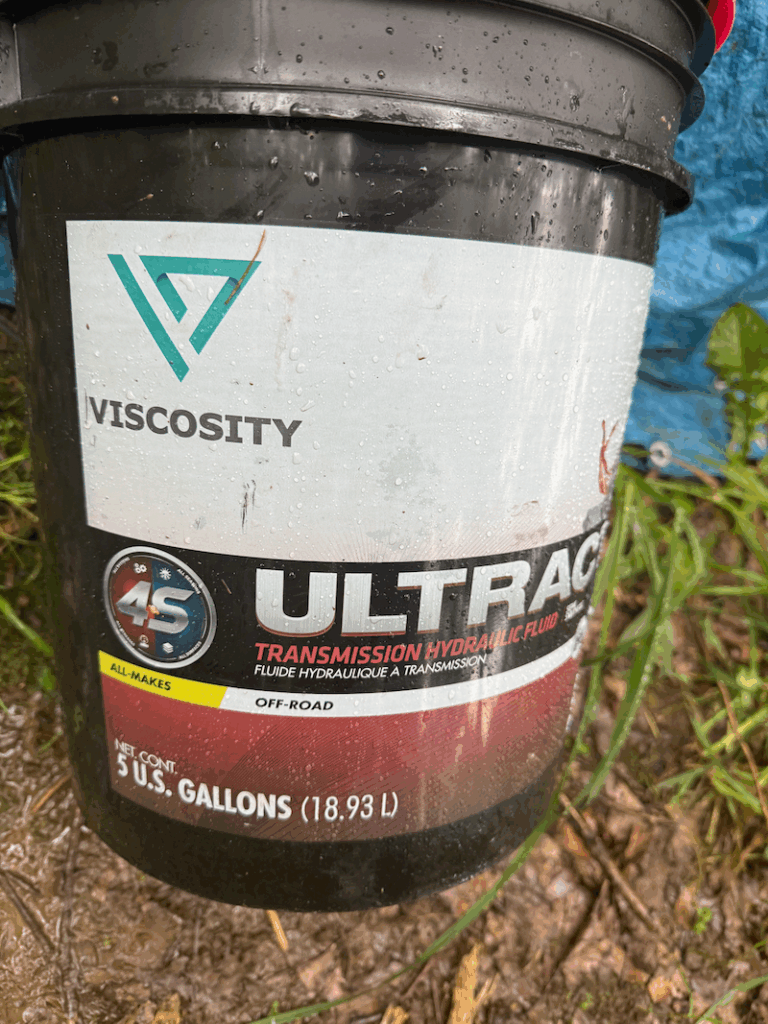

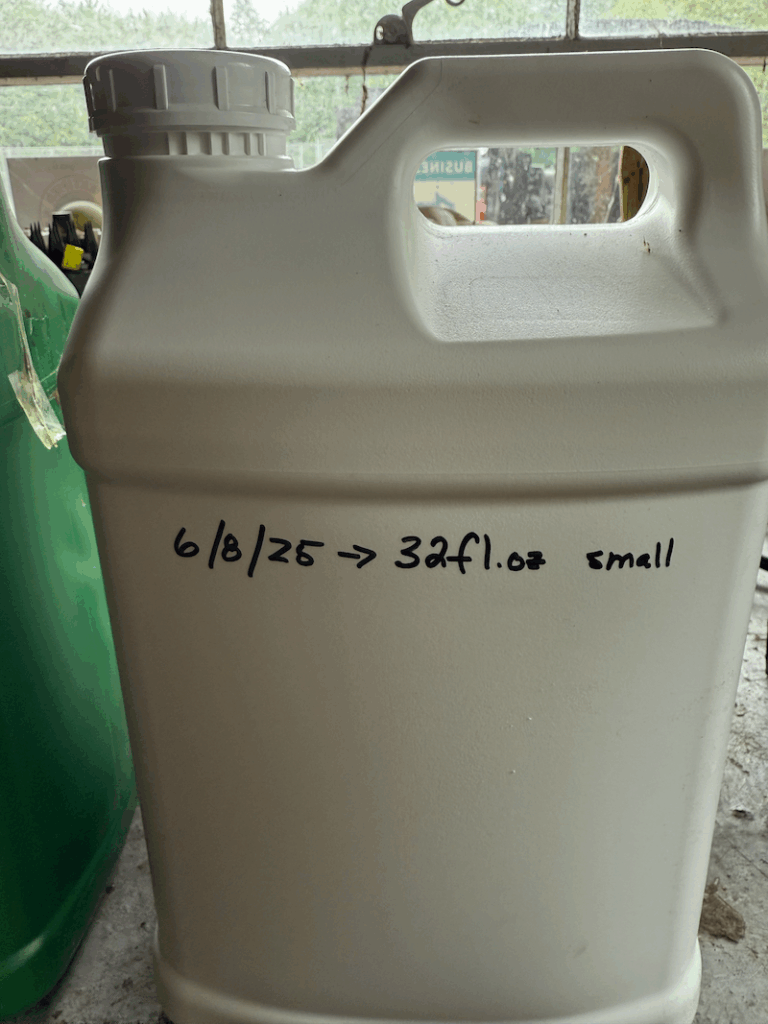

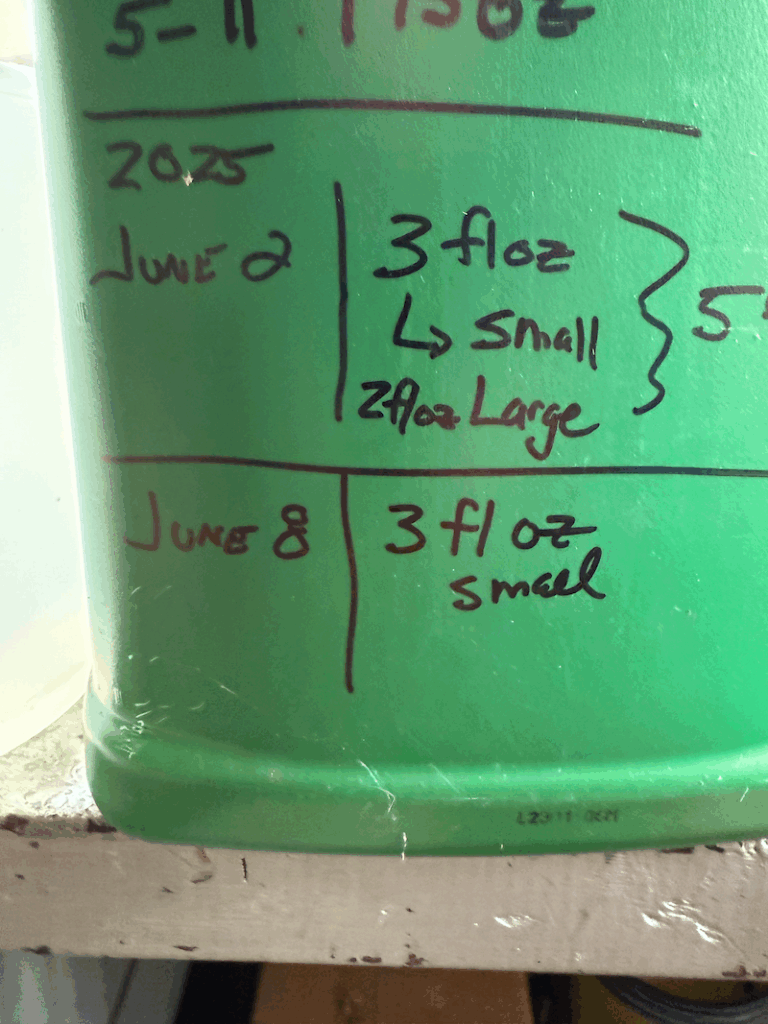

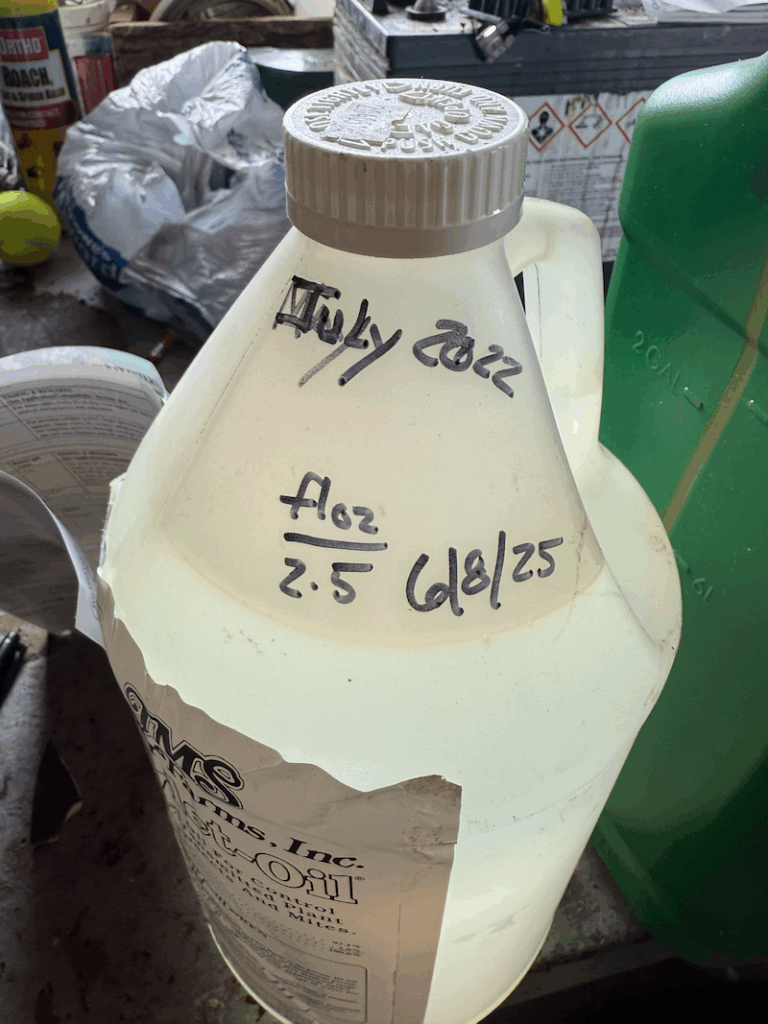

On an unrelated note, if you would ask if you could see the pictures a Farmer takes during the course of their day, I’d bet many would look like this…

Essentially it consists of images of a combination of the following; things I did at the Farm, things I need to do at the Farm, things that broke/need fixed on the Farm, how much of X, Y, or Z of which product(s) I used, etc.

It’s The Little Things

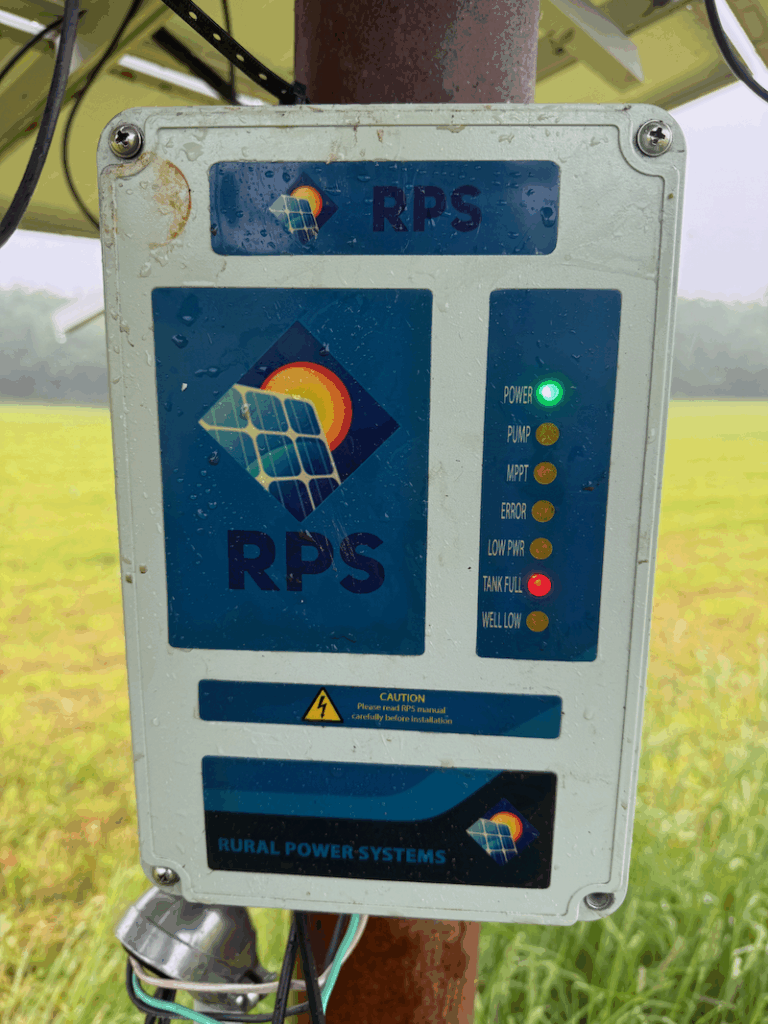

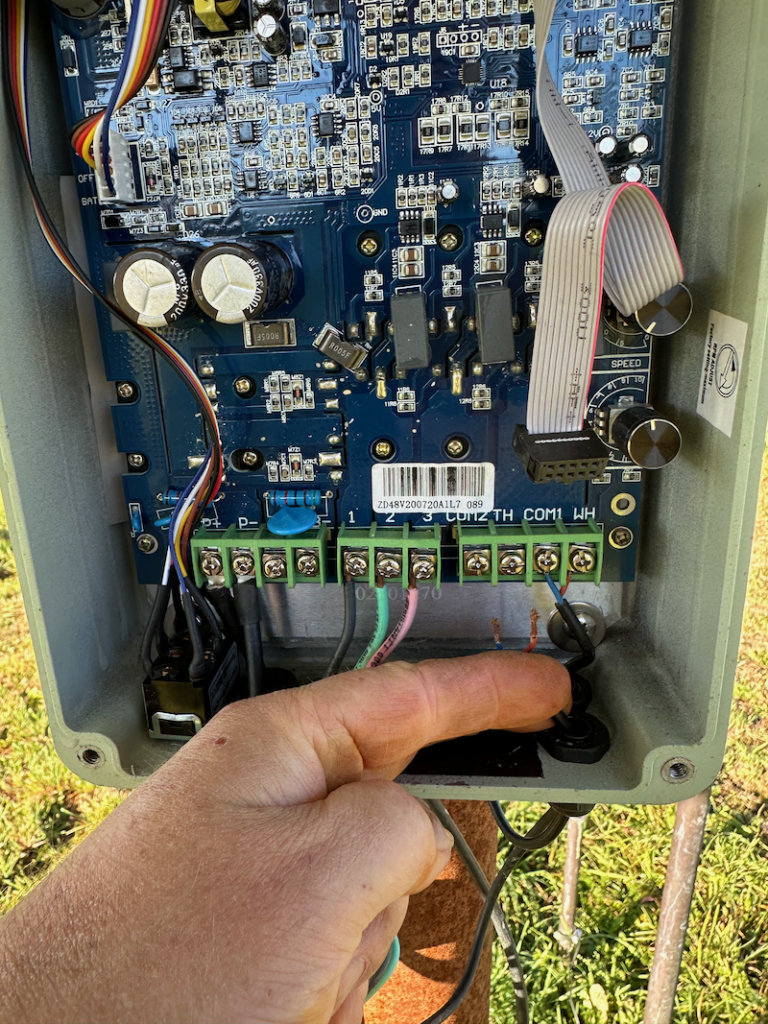

I was able to get the RPS control unit in place and was going to turn the system on, however I realized I needed to have the filter re-inserted – we take it out at the end of each season. I did at least test it and appears all is good. Yeah, one small win.

At this point, there’s not much one can do except continue the regimen we’ve always followed with nutrition, drip irrigation, fungicides, and insecticides, hope for better weather in June, and keep our fingers crossed. Feel free to keep those fingers and toes crossed along with us 😉

A Fresh Start: 2025 Hop Season in Full Swing

Emergence and Flame Weeding

We play this “game” every Spring; “when will the hops show themselves”?

This Farmer will admit he does not possess the greatest memory, not by a long shot. However, at this point, I feel like I have a pretty good recall for what needs done and when here in the hop yards. So when the bines hadn’t started poking their heads above the ground by early April, to say I was “concerned” doesn’t come close.

Was there something in the mushroom compost we put down at the end of Fall last season? Was there not enough snow to insulate the crowns over Winter? Has it been too cold so far this Spring? I was freaking out a bit to the point I felt like by April 5th, the entire season was already lost!

As is evidenced by this blog, I take A LOT of photos through the seasons. So much so, it becomes a research tool for us, much like the records we keep annually for our CNG certification. Why it didn’t strike me to just review previous season’s photos for this time of year, I’m not certain, but I didn’t until I’d already scared myself silly through the latter part of April.

And then I did, and then all was good – we were indeed on schedule for the growth of the bines for this time of year. So on it’s own, that revelation felt good, but when I realized in actuality we were (for the time being anyway) ahead of schedule as when I’d put the work schedule together, next up was flame weeding. Most Springs, by the time the schedule allows for that, that hops are a bit further along than we’d like because that means by the time the bullshoots die back and the good shoots start going, it’s a shorter time frame to the Solstice.

The Summer Solstice is when they top out on the trellis, and then focus more on sidearms and then burrs, which then become the hop cones. There isn’t a great deal of complicated math in this job, it’s a basic formula; the taller the bines, the more side arms get produced, which means more burrs for more cones for more beer. Long story short, things need to be kept as close to the yearly schedule as possible, and so far, we’ve been slightly ahead of the curve.

Side Tilling and Compost

As in most large or commercially designed hop yards, our hop crowns are spaced 3′ apart. Once I’ve gone through and flame weeded, it’s not possible to see at a glance where those crowns are, and that affects dropping and placing the coir. We use the “V-trellis” system and two overhead cables, which means each hop plant gets 4 pieces of coir attached to it.

High above the plants at the cables, two pieces of coir are tied side by side. One side goes to the hop crown on the left, the other to the crown on the right, and that’s mirrored on both parallel cables. So since we try and get the coir hung before the hops start regrowing after flame weeding, we need a visual cue, hence the orange survey flags. In the large yard, where we have about 1/3 of the yard replanted at present, another issue we noticed is that the hills we’d built for the new crowns got mostly washed away, again thanks to a lackluster layer of snow insulating the soil.

Side tillage accomplishes two tasks; first, it creates churned soil that we can then “hill up” on the crowns to help build the organic material protecting the crowns, and second, it then removes weeds that have grown along side the hop hills and helps control the weed growth directly around the hop crowns when we bring that extra soil up and around them.

It Can Stop Raining Any Time Now

Speaking of looking back, it also felt like we’d been getting more rain for this time of year than we had been of late. Various online resources, including our own Davis weather unit, which includes a rain/precipitation measurement tool, showed that we were indeed a few inches above the average for the last five years.

Obviously, crops need rain, just as we all need water, but too much can be bad not just for the crops, but trying to get work done for those crops. Heavier equipment can’t be used as it bogs down in wet, muddy soils. With rain often comes wind and high winds can make work up in the “siege tower” dangerous. Often, working in the rain, a light or moderate rain, is actually quite nice; no bugs, cooler, weeds are easier to remove, and a number of other plusses. It’s when it becomes heavy and is accompanied by higher winds that it really puts a wrinkle in our work plans.

And that in a nutshell has been the 2025 season so far for the most part; wet.

and yesterday, and the day before

Stringing and Training

The last set of tasks for the pre and early season work is tying the coir to the cables, dropping them to the crowns below, “punching” in the coir next to the crowns with “w” clips, and then training 2-3 bines per each coir. Sounds so quick and simple when you write it down, in reality however, it’s hours upon hours and multiple days of work. In the grand scheme of things, it is probably the most important job of the season as if it doesn’t get done right and within a certain window. enormous problems arise.

As usual, I was grateful to have the help of two of my brothers, Mike and Devin. Neither are particularly fond of heights like I am, but Devin volunteered to join me in the tower for the stringing of the coir to the cables while Mike drove the tractor down below, towing the tower, tying up lines down below, and anything else we needed.

Would it have helped to have at least two more sets of hands? You bet, but it’s hard to find folks willing to do this kind of work, paid or volunteering for it. But here we are – 2025 hop season is underway!

siege tower

Poured in Pennsylvania: A Documentary Showcasing PA’s Craft Beer Industry

Posted on December 19, 2024 by Joshua

Poured in PA began as a documentary project from GK Visual showcasing Pennsylvania’s craft beer industry. Poured in PA the film (2018) was featured at film festivals across the country, earning dozens of awards, including a nomination for a Mid-Atlantic Emmy.

While many breweries throughout Pennsylvania were part of the feature-length documentary, it was impossible to include them all. There were more breweries to visit, and more compelling stories to share. This evolved into Poured in PA: The Series, which allowed us to do just that.

Hosted by Danielle Hartman, each episode tells one or more stories related to Pennsylvania’s craft beer community. Our star-studded lineup represents breweries from every region in Pennsylvania! Learn more about us at: https://www.pouredinpa.com/

Straub Brewery “Keller Ale”

Posted on December 19, 2024 by Joshua

St. Marys Keller Ale is a spin on the classic style of Kellerbier from Franconia, Germany. Combining our lager brewing heritage with ale yeast instead of the traditional lager yeast we’ve created a smooth drinking beer with some fruity esters that compliment the mild bitterness of locally grown Cascade and Nugget Hops from Hoffman Appalachian Farm.

Found Only At The Straub Brewery Taproom

Untappd

For the Love of Farming – Before One Season Ends, the Next One Has Already Begun

Posted on November 12, 2024 by Joshua

Farming could be considered a variation of insanity if you truly do exactly the same thing year after year, however IMHO, a good Farmer…while toiling away in the fields year after year is the same…the tools, techniques, and tact must adapt for it to thrive.

Let me clarify this blog’s featured image in regards to farming. Yes, essentially at its core, farming repeats processes year after year. Till and plant seed (or in our case, tend to the perennials), cultivate, feed and water throughout the season, harvest and process, then prep for Winter. Next year, do it all over again.

And for most small, independent, family-owned farms like ours, that means we rely on very manual, hands-on processes. It is time intensive, it is labor intensive, and most days, it is exhausting. That can be the insanity part. However, even though those core, foundational steps do take place one season after the other, what moves it from insanity to creativity and innovation in my humble opinion – heck, I’ll say it – to hope and lucidity – is a concept I’m stealing from my professional workspace in agile software development – “inspect and adapt”.

The Inspect and Adapt (I&A) is an Agile Release Train (ART) event. It engages all ART stakeholders alongside the Agile Teams in reflecting on progress and identifying improvements. It is structured into three parts, the PI System Demo, a quantitative and qualitative measurement review, and a retrospective and problem-solving workshop. The goal of the Inspect and Adapt is to make the ART better by identifying and solving big issues. This is done by focusing on what has actually happened over the last PI rather than what was supposed to happen.

Apologies for appearing to switch gears from Ag to Tech, but as with everything in this Famer’s life, worlds collide and elements of one are brought to another and things make more sense, to me at least, when doing so. Inspect and Adapt, the basic tenets of it, are not unique to agile software development. In a nutshell’s nutshell, think of it as “shake things up”, “chart a new course”, or even “shifting gears”. In terms of software or product development, it’s an event where everyone involved in the development process – one team or a team of teams – reflects on the work that’s been done, assesses the good and the bad, and then identifies what’s left to be done and what improvements should be made.

This is an ongoing process at our Farm, and I would suspect at most others, both our size, those smaller, and certainly those much, much larger. It truly would be “insanity” if we just accepted things as they are, and didn’t attempt to improve our processes and make things more efficient.

Now I’m not talking on the scale of a GPS-enabled tractor in an enclosed, comfort-controlled cab using satellites to plant seeds or remotely controlling equipment to complete tasks from my iPhone. If that’s Farming to you, you should stop reading now, because that’s not what this guy considers Farming. You’re a desk jockey or a gamer with an interest in Ag.

I’m talking about making small improvements while still staying core to what I consider Farming; outside in the elements, hands in the dirt, sunburn on the neck, before-dawn-to-after-dark, physical work, but with the analytical mind of a product manager or system architect, always seeing what can be improved and done so within current resources. And while you’re focusing on the task at hand, you’re always making mental (and physical) notes for this same time next year. At the end of the day, and certainly before the end of the current season, you’re already putting plans in place for next year’s shot at it.

So possibly, “sorta insanity” 😉

And as I fell behind, again, this year documenting our work here in the blog, I’ve put together a summary write up and accompanying photos, grouped in sections. Follow along, but, “Please use the handrail, it’s for your own safety.”

Throughout The Season

For the most part, 2024 was a pretty standard year.

Coming off the success of having our hops exclusively used in our local brewery’s Keller Ale in last year’s brew, the hope was we’d make it happen again. And spoiler alert, we did 😉

One issue we did experience – one not unique to us but to every other local hop grower we know here in Pennsylvania and as far away as Michigan – was a stunting of the growth, and as a result, a decrease in yield. You can see in the photo below, “Harvest isn’t far behind”, taken after the Summer Solstice when the bines need to be to the top of the wire, that just a handful made it. While we’re all still somewhat scratching our heads as to what exactly happened, it appears some unusual, early season temperature fluctuations temporarily halted the growth.

All in all, we faired better than most realizing about 75% of the yield we saw in 2023. On another note, we celebrated our parents 65th wedding anniversary with a small celebration at the Farm sporting our previous family reunion shirts, “It’s A Brock Thing…You Wouldn’t Understand.” 😉

use what you have 😉

passing through

decorative sunflowers

Tidying Up the Irrigation Tank

One thing we noticed at the start of the season, was one of the driplines in the small hopyard was really intermittent in watering. Opening up the line, we realized that there was a fair deal of iron clogging the emitters. Now we have a filter way up at the tank to capture as much of the iron as possible, and we flush that filter weekly, however, it appears over the last two years, enough of it has settled in the bottom of the tank, that it was getting into the main line and then into the driplines.

Our 5,000-gallon irrigation tank is quite tall as you can see in the picture, and it’s not as simple as sucking it out with a shop vac or cellar pump, which we’ve done before. That fine layer of iron silt is like mud and the only way to get it out, as it sits a couple of inches below the outflow port, is to get a heavy-duty vac and use of combination of water flushing and vacuuming to get it all. As such, we reached out to Buerk’s Septic Service who did a great job, in a pouring rain no less.

Going forward, we’ve replaced the filter and changed the schedule from once a week or twice a week or more for backflushing it.

Large Yard 2.0

Another bigger change in 2024, was starting to replant the larger hopyard we tilled under a few years back. We were getting inconsistent growth in the varieties up there, and honestly in those earlier years, we just didn’t have the experiencial knowledge to work a second, much larger yard. We feel like we’re in a better place now.

So as to not totally jump the gun, we replace only 1/3 of each of the five rows and we didn’t string them, we just wanted them to establish and grow without worrying about any harvest in 2024. Based on how they do in 2025, we’ll determine if we’ll finish each of the respective rows with those varieties or keep them at 1/3 planted for the time being.

Thanks to the good folks at The Diamond Perk who were kind enough to collect their spent coffee grounds all season, we added those to our composted horse manure and it made for a great blend for the new hop crowns.

and horse manure

Farm “Truck”

I’d be remiss, at least in my opinion, if I didn’t share a few photos of my beloved ’08 Honda Element, stepping in time after time as the official Farm “truck” at HoffAppFarm.

The Harvest

As mentioned above, even with a slightly smaller yield, we were kept on our toes from March through harvest weekend, which as is traditional for us, is all three days of the Labor Day weekend.

12+ hours each

Prepping for Winter

After this year’s harvest, we had a little break in between where the Mrs. and I were able to get in a much needed, long anticipated trip to Maine, New Brunswick and Prince Edward Island, as well as Nova Scotia which was incredible. What wasn’t so incredible was getting back realizing we’d run ourselves ragged and were completely exhausted!

After recovering, no rest for the weary as Jenn joined me in D.C. for a work-related conference. She worked during the day and then joined my colleagues and I after we finished up. My co-workers from Agile Hive (Seibert Group) made the trip over from Wiesbaden, Germany and it was great to see them in person after over a year!

Then quickly hopping (yes, that’s always “pun intended” here) back into the Farm work, brother Mike and I spent the next 3 weekends prepping all the beds for Winter, getting all the irrigation lines and tank drained and water blown out, preparing equipment and such for a 5 month nap.

ready and waiting

See You In 2025!

And that my friends, really is the Clif Notes version (with pictures) of the 2024 season. Hope you enjoyed following along on the socials and now here on the website. We wish you and yours a wonderful Thanksgiving, Merry Christmas, and Happy New Year – and we’ll see you in 2025!