A Certified Naturally Grown Farm - Saint Marys, Pennsylvania

A Family Hop Farm’s Love of Stringing The Hopyard

Posted on May 23, 2024 by Joshua

For hop Farmers in the Mid Atlantic, the middle of May means it’s time to string and train the hops! That’s where we found ourselves recently @HoffAppFarm. While exhausting, stringing the hopyard is something this family hop Farm loves.

We’re up in the “siege tower”, or in my case, strapped to the outside of it on an extension ladder. Hundreds of coir strings are waiting to be tied and punched into the ground. Then comes wrapping 2-4 bines around them clockwise to begin their journeys to the top of the trellis.

I drove up the night before, as these typically mean even earlier than usual starts. I’d leave the 2+ hour drive for the night before to get some things in place. This would then leave the morning exclusively for final prep. The Friday evening before did not disappoint with some incredible scenery!

Saturday, In The Park (Hopyard)

Saturday morning started as usual with a healthy dose (if that’s possible) of coffee and a jelly donut. Not really on my typical breakfast list, but Mom snags them, and well…hard to pass them up 😉 Up to the barn to to start prepping things. The other reason to head up the day before – it’s a good practice to let the coir soak overnight. It’s much easier to work with as it’s more flexible.

The next step would be to assemble all the tools necessary for the day. This includes w-clips, coir punching rods, etc., fire up the tractor, prep the “siege tower” and rig the outer ladder. This year would be a little different in that I’d have some help with me up in the tower. Most years it’s just me in the tower and brother Mike or brother-in-law Bill on the IH674.

PSU Grad to the Rescue

Louis Franyo, or “Fin,” joined me. Fin is a recent Penn State engineering graduate. He was part of the PSU team that worked on designing a second oast to add to our toolset. The oast lets us dry down the hops for long-term storage.

Thanks to the efforts of our good friends at the Pennsylvania Technical Assistance Program (PennTAP) to secure the funding and the Learning Factory at Penn State’s College of Engineering, the team’s efforts yielded a different style oast that will increase our capacity and shorten the drying time. At our initial on-site visit, Fin mentioned an interest in helping out. During the season, stringing is one of those projects we typically seek outside help.

Make Due With What You Have

Now one thing about our original, smaller yard, we didn’t know completely what we were doing when laying it out. Yes, we spaced correctly with the rows 15′ apart. Yes, the hops rhizomes 3′ apart in the hills, but the cabling setup was almost comical. These are heavy duty wire rope and all the related hardware to go with them. We used a bucket truck to position me in place to string the upper cables some 20′ above the ground.

Wranglin’ Cables

While I’m no longer afraid of heights after many years of climbing, it’s not easy. It can be difficult trying to manipulate heavy cable, ratchets, in a very small bucket at that distance off the ground. Kudos to all the line-workers out there! Long story short, we originally wired the small yard to accommodate only 1 overhead wire per row. A second line is added in commercial yards to create what’s called a “V-trellis”. This is essentially another row to tie into, expanding the overall yield without increasing the footprint below. in 2018 or 2019, we added that second set of wires.

Well as it turns out, the anchor cables do not allow us to work from outside the rows. Rather, we have to do all our work from the main alley in-between them. That means the two outer cables on either respective side can difficult to reach while not driving the tractor’s tires over the hops below. So I came up with an idea to strap a ladder to the ouside of the rig to access those cables. What that also means however is I’m essentially dangling out in space on an extension ladder not leaning up against anything as they’re designed to be. It’s then held in multiple places with ratchet straps. I’ve adapted to it.

One Ladder? Why Not Two?!

And this year because of Fin’s stellar help, he could remain in the siege tower to string the two inner rows, while I simultaneously did the outer ones. We did have to make an up-and-back trip as we couldn’t have him string both inner rows, as for me to get to the other outside row, we’d have to come back and that coir in the alley would get in the way. The ideal solution would be to have two suckers…I mean helpers…secured on 2 outer ladders with 2 people in the tower and do it all on one pass. Maybe next year 😉

Next Up: Punch The Coir and Train The Hops

Once we got through both directions, it was time to park the tractor and the rig. Next we secure the coir with W-clips using the coir punching rod (I think it’s actually called an applicator rod but I like our term better). As mentioned, we use a V-trellis system so in the shape of (you guessed it!) a “V” we drop 2 lines down per plant from one cable, and then another 2 for another “V” to the plant from the other cable. As such, each plant has 4 pieces of coir boxed around it. It takes a little practice to get this process right, but I can do it in my sleep at this point.

Train ‘Dem Bines!

While Fin and Mike were punching in the coir, I trained the hops onto it. This also means simultaneously weeding, and then training 2-3 hop bines per piece of coir and wrapping them clockwise as they grow vertically following the direction of the sun above. Honestly, if you’re not taking advantage of a weeding opportunity at some point while doing any project in an organic hopyard, you’re probably doing something wrong 😉

Training hops, especially when you’re probably about 2 weeks behind schedule can be tricky, as they’re now over a foot long and they love to wrap themselves around any and everything they can find; each other, the drip irrigation support, the flags used to mark the center of each hop hill…anything! So part of the work is detangling them and then getting them on the right path up the coir. It’s easier when they’re a bit shorter, but due to some other issues we had to address earlier in May, this was our first chance to string.

“Kissed By The Hops”

Fin assisted with this process which was great as it’s usually been me the last few years. Hops have small hairs on them, like tomato plants, which give them their climbing prowess. As I’ve mentioned before, working with them so closely, you’re often “kissed by the hops” all over your forearms and hands as they’re a bit scratchy.

Additionally, at this point the clouds had burned off, the sun was out, and the humidity was classic central PA on a near-Summer day, i.e. disgusting. As a result, this totally manual process of detangling, training, weeding with the sun beating down is not fun and I hate to ask others to help with it, even when they’re paid. Alas, we did, “gett’er done”…or is that “gott’er done”. Either way, we have finished it!

Next Steps

Our next Farm day(s) will consist of final weeding of the small yard, and re-installing the drip irrigation system, starting the solar pump up and letting it fill the tank, and getting the timers in place for twice-a-day drip irrigation. There’s also a fair amount of prep work in the large yard for the new hops. We’re not replanting the entire yard this season, just a small subsection of it, with four new varieties (Chinook, Comet, Saaz, Williamette) in addition to a new set of Cascade we already work with. That will also require adding partial drip irrigation to that yard as well. The hope would be to have that yard fully back up to capacity in 2025 or 2026.

That’s what’s “hoppening” (I’m entitled to Dad-joke status at this age) from the Farm. Catch you next time!

Spring 2024 Hops Update | Spring Regrowth | Sprouting

Posted on May 6, 2024 by Joshua

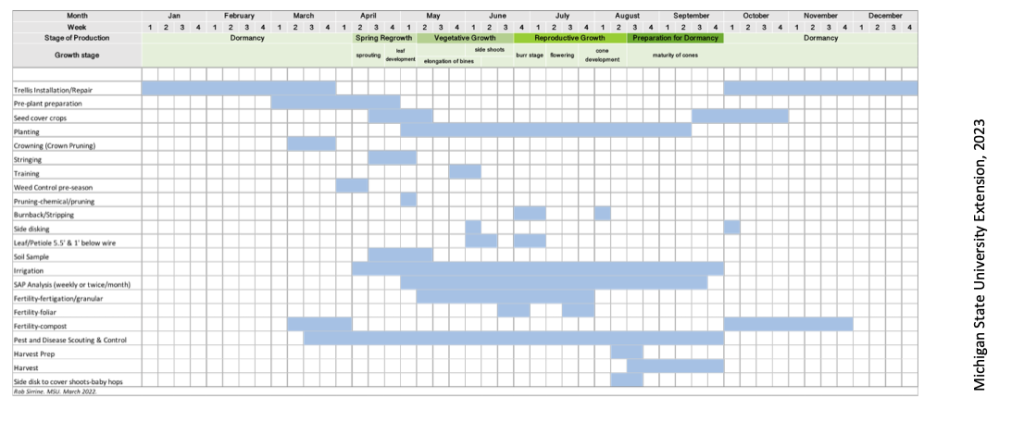

The good folks at Michigan State University (MSU) Extension have been a great resource to us over the years. They provide monthly webinar sessions for growers on a variety of timely in-season topics, their free Hop Management Guide, and have been available via email for questions and concerns. Now, they’re focused more on conventional, larger hop Farms based in and around Michigan, but we still find a lot of useful content for our region and our size of family Farm operation.

Management Activities Guide

The following is their “Management Activities Guide” which is slightly ahead of where we’re at, but it’s been a great resource in planning out the season and roughly where we should be.

One of the earliest activities for the yard is flame weeding. It’s not so much for the weeds as we’ll be dealing with those all season long, it’s more so to 1) kill the “bull shoots” that come up first and 2) help in the regimen that includes organic fungicide, to help rid the yard of any instance of downy mildew. Bull shoots are the earliest of the bines that appear and although they’re exciting to see as the first in Spring, they also tend to be the weakest and least productive. So we bid adieu to those early along with the first flush of weeds.

We will continue to spray organic fungicide for another week or two just to help guarantee downy mildew never rears its ugly head. Next was reinstalling the solar array’s control panel and getting that all hooked up. This will be the first season using the new wireless tank full sensor, along with the solar powered transmitter/receiver configuration. I expect some tweaking with placement so they’re “line of sight” but hopeful beyond that, it’ll just work as it should!

Sometimes Still Learning the Hard Way

We found out the hard way the other week that our tractor bucket’s hydraulic lines were ready to retire. And by “retire” we mean they blew out when trying to turn the compost pile. As with many things, sometimes we are forced to wait until something breaks before replacing it. This probably really should’ve happened with the dealer originally worked on the tractor years ago, however we did get another 5 years out of them so we’ll consider it a draw.

The ratchets and support lines/cables for the upcoming drip irrigation are also in which then really helps to make it feel like things are coming together. Next weekend will be the stringing of the small yard and training of the flush of new, healthy bines 🙂

2024…Here We Go!

Posted on February 23, 2024 by Joshua

We’ve been waiting all Winter to dive back into the hop hills, and if Punxsutawney Phil is correct, shouldn’t be much longer now. A recent walk of the fields, checking for the emergence of shoots, although turning up negative, did once again inspire your hop Farmer to dive back in as soon as conditions allowed.

So why the reference in our featured image to the classic Disney animated film, “UP!”? Well, it’s a reference – honestly admitted to by this Farmer – that my focus and interest can and does get pulled in a hundred different directions. In particular, as we’ve been planning and making ready for the upcoming season, we have a couple of “irons in the fire” we’d like to share.

When we applied to compete and were selected to do so in the 2023 PA Wilds Big Idea Contest, the obvious hope would’ve been we’d walk away with some funds to tackle the multitude of projects here that we just haven’t been able to afford, but very much need; a new or modified hops harvester, larger drying capacity for the hops, pelletization and packing, replanting of our larger hopyard, compost windrow turner, etc. And although we didn’t walk away with any prize monies, we made some incredible connections that have been paying off in different ways ever since.

Our biggest connection has been to the incredible team at the Pennsylvania Technical Assistance Program (PennTAP) at Penn State, which is “a statewide technical assistance organization charged with supporting Pennsylvania businesses and anchor institutions — including manufacturers, municipalities, educational institutions, entrepreneurs, farmers, and economic development agencies.” In particular, we’d like to call out and thank Heidi Shadeck and Krista Schneider for putting us in touch with two teams at Penn State who are working on two separate projects. One is the re-engineering of our hops harvester to improve the speed and efficiency of the machine, and the second on the creation of a much larger and higher capacity oast (hops dryer) as part of Penn State College of Engineering’s Learning Factory.

Not only were they able to coordinate and assist our applications to the programs, but they were also able to use related grant funding to pay for the vast majority of the work being done; CAD design, materials, construction costs, etc. We can’t thank Heidi, Krista, and the entire PennTAP team enough. More on these projects coming soon!

In addition to our work with hops, we’ve also been looking into hemp, biochar, small grains such as malting barley and Kernza®. As part of our ongoing efforts to keep up and implement (when we can) the latest in sustainable and regenerative agricultural practices, we’ve been on the lookout for No-Till equipment. Our goal is to build the health and vitality of our soil first, which will then translate into healthy crops which are less dependent on off-Farm inputs, more resilient to pest and weed pressure, and with greater yields as a result.

After many years of searching for No-Till equipment to rent or lease – a difficult endeavor as it’s not a practice that has seen much interest in our region up in the PA Wilds – knocking on enough doors paid off! In a recent email with the good folks at the Elk County Conservation District, we got the great news that funding was put towards the purchase of a No-Till seed drill and it would be made available to Farms in Elk County in 2024. Score another for us, and collectively, for all Farms in the county!

Members of the Elk County Farm Bureau, Ernie Mattuiz and Rodger Auman, are shown with Elk County Conservation District board members Way McMinn and Joe Labant, along with District Manager Kate Wehler and Resource Conservation Technician Alyson Bevacqua (photo submitted)

Earlier this month, we also attended the annual Pasa Sustainable Agriculture Conference in Lancaster, PA as your friendly local hop Farmer began a part-time position with the heralded organization in February 2023 as a Research Data Technology Specialist. Hard to think of a better way to match the efforts at our Farm, with the larger sustainable Ag community than working directly for it.

It was at this conference we met up with another great group of Penn State folks involved in a new Solar in Agriculture research study. This began with a survey we participated in during the Summer of 2023. Given our recent foray, albeit somewhat small, into solar with our pump, storage tank, and drip irrigation system, we were glad to be part of the wave of Farms exploring this technology. We were honored to then have the team visit the Farm last week to see our application of the technology firsthand and discuss our plans for it down the road.

So by now, you might better understand the reference to Dug’s “squirrel” reference. Head on a swivel nowadays, from one project to the next!

Hop Farm | version 2.0

Posted on December 15, 2023 by Joshua

“Forward, always forward, everywhere forward“

Boniface Wimmer, O.S.B.

Founder & Archabbot, Saint Vincent Archabbey | Latrobe, Pennsylvania

1809 – 1887

It’s that time of year – harvest is behind us, hops are put to bed for the Winter, and there’s no work left to do in the fields. It’s time to sit back, reflect on the past season, and start making plans for next year.

And what a great way to reflect, than by literally drinking the “fruits of your labors”…

The next installment in our Brewery Exclusive Series is available starting today!

St. Marys Keller Ale is a spin on the classic style of Kellerbier from Franconia, Germany. Combining our lager brewing heritage with ale yeast instead of the traditional lager yeast we’ve created a smooth drinking beer with some fruity esters that compliment the mild bitterness of locally grown Cascade and Nugget Hops from Hoffman Appalachian Farm.

This brew is 5.5% ABV, unfiltered, unpasteurized and must be purchased cold and kept cold. Only available in 24 loose bottles, 6pks and draft at our Brewery Retail Store and at Straub Brewery Visitor Center & Tap Room

Phase 1 Complete

It’s hard to capture the feeling at the moment finally seeing this come to pass! It’s been a joint effort for certain. So many hours, primarily volunteered, by family and close friends – from putting in the hop yards, stringing the hops every Spring, tending to the hills through the season, special projects like putting in our solar irrigation system almost exclusively on our own, and especially at harvest time. There are many, many individuals are part of this accomplishment!

So what’s up with the “2.0” reference? Well, having a full-time job as a technical writer for an Atlassian partner/app developer, versions and builds are part of this Farmer’s other gig. But as with many aspects of life, things bleed into each other, many times quite beautifully and organically. The 2.0 reference is a common saying in our field of work, but it’s also found its way into the everyday vernacular. Webster’s defines it as “used postpositively to describe a new and improved version or example of something or someone“. You may recall sayings like “Web 2.0”, or “new me, version 2.0”.

In short, it means a new rendition – hopefully better or more improved – of an original product, service, or deliverable of some sort. In this instance, it’s a turning-of-the-corner, cresting of the hill (even if it’s a known false summit), a sigh of relief. We’ve been working on this for years, refining our processes (many of which are still quite manual), building capacity, learning and improving along the way. By no means does it mean we’ve arrived, just that phase 1 is complete.

The Plan…Wait…There Was A Plan?

Well, sort of. The original plan after moving back home from Colorado was to start with a small vegetable operation, possibly a CSA. And that was the route we started following. Put in a small garden plot where the small Hopyard now sits, figured out a temporary solution for irrigation, and then we decided to kick it up just a notch.

With not a lot (read “ZERO”) of funds, we constructed a homemade high tunnel using a technique found on YouTube. Using lumber we either had on hand up in the barn attic, or purchased from one of the local lumber yards, along with some PVC pipe for the ribs, and plastic sheeting from one of the commercial high tunnel manufacturers…even had a set of storm doors on either end that were leftovers from the house…we got it in place. And then came the winds…

“That spot in the field, although it gets the most sun, it also gets horrendous wind.

Oh well, it’s gotta be able to take it…bring on Old Man Winter!!”

Long story short, it DIDN’T take it. The wind got in under the base, and even with it secured with multiple stakes into the ground, kicked it up, flipped it like a discarded plastic grocery bag, and deposited it about 15 feet about to where I was standing when this photo was taken.

High Tunnel = 0 | Wind = 1

Shortly after this event, I started to research the National Resource Conservation Service (NRCS) and their Environmental Quality Incentives Program (EQIP), and their grant program for high tunnels. In 2012 we applied and to our surprise, were awarded a grant for a rather large one, approximately 100’x 20′ for 4-season vegetable production. Truly seemed like maybe, just maybe, we were on our way.

We received the high tunnel in September 2012 via semi-trailer and unloaded it by hand (no tractor at this point). It was a bit overwhelming truth be told. If you think putting together a bed from IKEA and those instructions are a bit intimidating, this was that on steroids. Thankfully my father-in-law is a mechanical engineer and after a little cajoling, stepped in to help. Thank God as I was in over my head and never would’ve completed it by year’s end, which is when the contract needed to be completed.

And so we worked just about every weekend between October and early December until it was finished.

And there it stood, where our small Hopyard now sits, for about two weeks. Then came early December, along with those inevitable winds again and an ice storm, and well…

High Tunnel = 0 | Wind = 2

I clearly recall that day. I drove up from State College as I normally do during the season, I’d brought my XC skis as I wanted to get in a jaunt after checking out the high tunnel. As you can see from the photo, we’d gotten a fair amount of snow – snow and ice actually – the combination of which must’ve collected on the North side of the high tunnel and it was just too much. As I trudged up through the snow from the barn, I could tell something didn’t look right. I got about 100′ from it and realized what had happened. I immediately dropped to my knees and let out one of the loudest WTF’s I’ve ever uttered.

I was resolute that this was the final straw, the message from on high that Farming wasn’t in the cards for me. Between the 90-minute commute, events like this, not particularly productive soil…I’d had it. Or so I thought. We did take a break in 2013 with nothing happening at the Farm. Luckily insurance covered the high tunnel completely and we were able to repay back the grant. Although obviously not our fault, we didn’t meet the NRCS/EQIP requirements for the grant. We also got “dinged”, meaning we wouldn’t be able to apply for another grant for a few years. It was salt in the wound considering it was a weather-related, freak accident but such is life.

“Why Don’t You Try Hops?!” – Famous Last Words

Then came 2014 and I’m working at Pennsylvania Certified Organic (PCO) as their IT person. Lots of great folks there, loved my work, a great combination of my new-found passion in Ag along with my traditional tech background. During a conversation with a buddy of mine there, he mentioned he was growing 2 hop plants in his space at the PSU community garden. Pretty easy to care for, and definitely didn’t need to have the near-daily “love” shown to them like a vegetable crop would (at least for a small-sized planting). And one might think with one of the nation’s oldest, independent, family-owned breweries in town the idea was to grow hops for their use. Honestly, didn’t even cross our minds. We just wanted to give it a go.

And so in 2014, that buddy of mine (Adam Seitz), my uncle David Hoffman, my Dad, and I put in 6 black locust poles we’d sourced out of the Altoona area. This became what is now our small Hopyard. We then found an organic rhizome grower out of North Carolina and purchased 20 Cascade and 10 Nugget hop plants. We grew them under lights for a few weeks and planted them in late Spring. We were essentially on the way!

Again, there was no specific plan as to what we’d be doing with the hops once we harvested them. At the time, Adam was home brewing so I figured I’d give him some and maybe if we were lucky, sell a few bags. As they say, nothing goes unnoticed in a small town, and sure enough, word got back to Straub Brewery that we were growing hops locally. They already had a great source literally down the street from them to use in some R&D brews, but this would be a larger volume of local hops than what they’d had available to them previously. And so, we dropped off our harvest at the Brewery- one that my Dad and I completed by hand, on our own, as they were growing on the bines – in about 20 minutes. Comical considering the time and effort it takes now with just those 30 plants having matured.

Now I will say that that first R&D brew you see in the boil apparently didn’t turn out as hoped. They’d used the term “grassy” which now, with a few years under our belts, makes total sense as it was the very first year they were in the ground, AND, we had little clue as to when we the right time to harvest (i.e. moisture content / dry matter levels)…we sorta guessed.

Luckily there still apparently was interest in having some specialty brews made down the road, either exclusively with our hops or used in companion with hops the Brewery sourced from their much larger, annual contacted providers. The Head Brewer contacted me by phone, a plan was hatched for a much larger yard, and that’s when things took off…sort of. The year was 2015.

We turned to our black locust supplier in Altoona with an order for 35+ poles and contacted a Hopyard supplies distributor in NY state for all the cables, connectors, and equipment we’d need. My Dad and I surveyed out the area they’d be planted in which is at the Northwest corner of the property. A wide-open field that our leasing Farmer rotated his crops in. We snagged about a 1-acre area, dropped in markers for the poles, and awaited the black locust delivery

In the interim, one thing we’d learned was that while Black Locust is naturally rot resistant (the reason why many Farm used the wood for fence posts), with the bark left on it, it’d degrade quicker as it was a habitat for insects to fester and degrade the wood. This came as quite a shock as it meant we had to find a way to debark all those poles. We dabbled with a bark stripper that fit on the head of our chainsaw and while it did a fair job, it was slow and damaged the poles in addition to taking off the bark. And so we resigned ourselves to every weekend spending at least a day, my Dad and I, using the classic hand tools of a felled bark spud, felled draw knife, cant hook, and a sledgehammer…yes a sledgehammer!

One of the great things about working at PCO was the folks I came into contact with. One of which, Tom Carey, who’d actually installed the network server at PCO a few years earlier and who I’d later work for at AccuWeather, told me that to really get the benefit of Black Locust, the bark had to come off, and a great way to do it was to smack it with a sledgehammer in a line which would help separate the bark from the core of the tree. Then we’d use the bark spud to peel it off. Many times it came off easily in these huge multi-food sheets, other times it was more finicky.

In any event, Dad and I spent hours up there going one by one through the logs, debarking them, rolling the debarked ones out of the way, and rolling a new one from the pile. It was hard work for sure, gave me a real appreciation for how it was done “back in the day”, particularly here locally in the original mills when Saint Marys was founded. Long story short…that already put us a season behind as we couldn’t plant the hops without the poles and infrastructure in place.

It was also at this point, that we realized we definitely did not have the equipment we’d need to run this expanded operation. We needed at the bare minimum a good tractor, a platform to string from, and a way to prep the soil…we had none of it, and again were struggling with little to no budget for what was essentially a hobby Farm at this point. We came across an organizer called Barnraiser which coordinates crowd-funding campaigns for just about anything under the sun. With a name like that, this must’ve been the group we were destined to go with.

And so from early October through early November of 2015, we put together and launched our Barnraiser campaign with the goal of getting enough funding for a solid, used tractor and any other implements we could find within that budget. Thankfully we met our goal and were able to purchase a solid, used International Harvester (IH) diesel tractor – ironically from my former boss at Appalachian Ski & Outdoors – along with a used commercial equipment trailer that would become our “siege tower”.

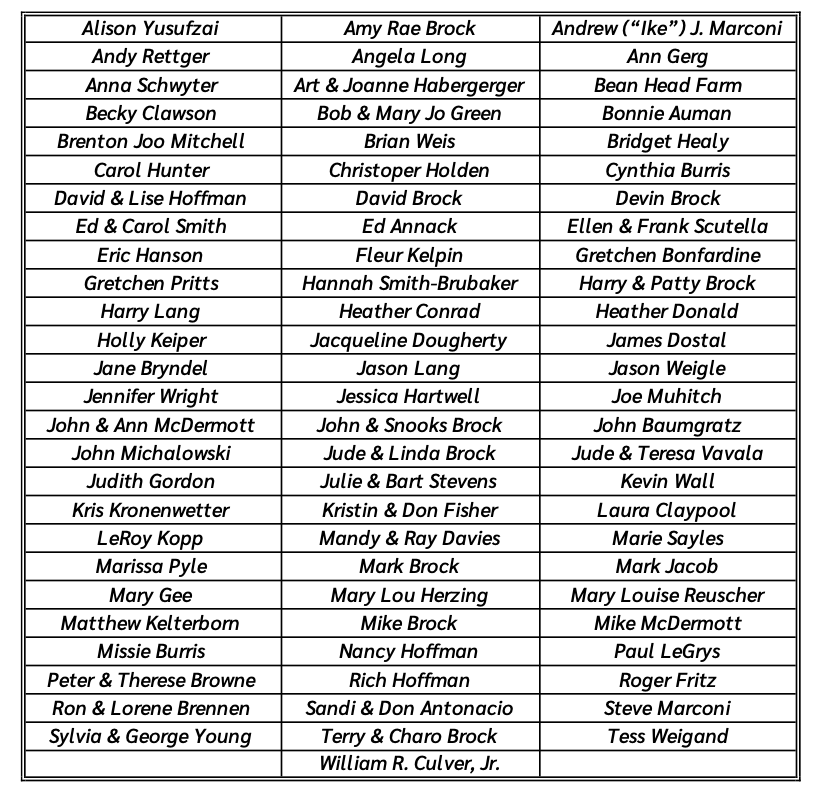

I feel it necessary to once again, thank those kind folks who helped make it all possible, we wouldn’t have been able to be where we are today without your support. Looking through the list, it’s a combination of heartfelt joy but also tinged with some sadness as I see a number of wonderful souls no longer with us.

Bigger Yard, Bigger Responsibilities, Bigger Headaches

I write that header with a slight smirk on my face. When we were approached about putting in a larger yard, we were very early in our hop-growing experience. As such, it was hard to plan and comprehend the amount of time and effort that would be involved in going from 30 plants to almost 500, from a quarter-acre to almost an acre of hops.

As this had been very much a “hobby” project up to this point, it was primarily me (Joshua) doing the majority of the day-to-day work and family members assisting with the bigger projects. There wasn’t a plan (or budget) to bring on additional help – full-time, part-time, or seasonal – to assist with those daily projects like weeding, mowing, training and trimming of the hops, spraying, etc. And so once we got the new hops planted in the larger Hopyard and strung, an effort that took 4-5 of us, it would then revert back to me as the primary, sometimes exclusive, field worker to maintain them and get them through the season to harvest.

It was, as the header suggests, a series of headaches, particularly given the time constraints at the Farm only 1 sometimes 2 days a week. In 2016, we had our original smaller yard with 30 rhizomes planted and then the larger Hopyard with 480 rhizomes planted. Yowza. It quickly became evident that I’d need to find a way to split my time between the yards over a day or weekend and that proved extremely difficult.

It was akin to just learning how to juggle, and then adding the unicycle, plates, and dancing bear the moment you feel you got the hang of the 3 rubber balls. The new hops arrived early due to a miscommunication with the grower, and the hills weren’t ready yet. So they sat in their flats for 3 weeks with my Dad watering them daily, while we rushed to finish the hills in the new yard and keep the small yard as tidy as we could. That is to say, the new hop hills weren’t properly tilled and prepped, and the small yard didn’t get strung until AFTER the Summer solstice – the point at which they should already be at the top of the wire. It was chaos.

We got the transplants in, again in less-than-ideal soil conditions, got the large yard strung, and away we went. Now we had five varieties planted originally in the large yard; Cascade and Nugget which we also had in the small yard, along with Horizon, Brewer’s Gold, and Vanguard. The three new varieties came at the request of the brewery and it should’ve been on us to check to see if those three varieties showed promise elsewhere in the Mid-Atlantic region where we’re located. Temporarily fast-forwarding to 2019, we determined they were not. We tended to them and encouraged them for the first 2 years, the third year they just kinda hung out in the yard without much care, as we worked to keep the Cascade and Nuggets going. By 2021 we’d decided we just needed to till everything under and start again.

Another Go At the Grant Process – Solar Power and Drip Irrigation

First off, thanks for hanging in there this long! I’ve started and stopped on this article five times at least over a month. My intent was not to create a post this long, but rather a summary of where we started and how we got to present day 2023. But as I got further along, I realized…

Sometimes The Light’s All Shining On Me

“Truckin'”

Other Times I Can Barely See

Lately It Occurs To Me

What A Long Strange Trip It’s Been

The Grateful Dead

Back to the solar pump and drip irrigation grant. When we put in the larger hopyard, we were already quite aware that getting a consistent volume of water and nutrients to the hops was critical. Getting those two critical components to 30 plants was realistic, to 500, not so much. For the small yard, we’d set up the old 250-gallon water tank we’d used years previous for our vegetable endeavor and purchased drip tape, and a basic timer for it. We then ran a series of hoses up alongside the field from the barn to the small hopyard and as needed, refilled the tank. Again, not ideal, but it worked.

Hops require a lot of water. I’ve seen estimates upwards of 16gal/plant/week. With some 530 plants that’s almost 8,500 gallons of water. It does rain a fair amount in our region, but nowhere near that level. Additionally, hops require a fair amount of nitrogen replenishment, particularly as they’re prepping for burr stage. Burrs become the cones. We wanted to be able to fertigate (liquid fertilizer) via our driplines. It was hard enough getting water to the small yard, there was no way we could supplement irrigation in the large yard. Thus we began research grants for irrigation systems.

We found one with NRCS’ Environmental Quality Incentives Program (EQIP) program, their “flagship conservation program that helps farmers, ranchers and forest landowners integrate conservation into working lands.” Working closely with our regional NRCS agents, we built and submitted our application and proposal and it was accepted! Yeah us…now we just actually had to put it in place. With the funds we have available, we knew the vast majority of the work would need to be completed on our own. The solar array, pump, pipes, hydrants, etc. would be expensive enough – we couldn’t afford to have a contractor do all the work for us – nor did we want that.

A wrinkle developed when we realized the original proposal from NRCS had us running power up from the barn to the pump. That was a two-fold issue. First, digging an electrical line from the barn to the pump was almost 1,000′. That would’ve eaten up a ton of the budget there. Second and more importantly, the barn was built in the early 1960s and we sometimes can’t run two large pieces of equipment at once as the breakers would constantly pop and need to be reset. It wasn’t wired for something like this. So we proposed adding solar to the system. This was something NRCS was very excited about as it fit directly into their mission.

The next hiccup however related to that was a solar pump really wasn’t meant to be pumping within an irrigation system this large and geographically spread out. As we’d be watering most likely twice a day at least, the pump would be working overtime and wouldn’t be able to push the pressure levels needed. We needed a way to store the water and transport it. Thus, the idea of an above-ground water tank using gravity to feed the system with enough pressure. Great – except the budget didn’t include that. So that part came out of our pockets.

You can read the entire story here, but not to rehash it here…it was a tough project, we were under a deadline we were certain we couldn’t meet, but somehow we did. And it’s been a God-send since day 1 of operation and every day since!

Fast Forward to the End of Season 2023

Coming back full circle here, I think, to where I started with this article 😉 this year’s crop was the first to finally make it into a production brew! We’re still on a high from it and I hope we never forget the feeling. However, there is the large hopyard that has to be replanted back to its original 500+ plant capacity, there are improvements in the harvester that the student cohort from PSU is working on for completion in 2024 (more to come on that), expanded drying capacity, pelletization and packaging…the to-do list is fairly large and aggressive.

We say farewell to 2023 feeling good about what’s been accomplished but looking forward to the possibilities in the years ahead. And so with that, we close this entry just as we’d opened…

“Forward, always forward, everywhere forward“

Boniface Wimmer, O.S.B.

Founder & Archabbot, Saint Vincent Archabbey | Latrobe, Pennsylvania

1809 – 1887

Snap, Crackle, POP!

The evening of Thursday, 21 July, Northcentral Pennsylvania was visited by a pretty intense storm cell. High winds, humid air, rain, thunder, and lighting…a classic thunderboomer.

As is normal during the week, I was at our place in Montoursville. When Jenn woke me up saying she’d heard things on our deck moving around, I went out to investigate. When I did, the way the wind was blowing was odd…starting low from the ground and then upwards, in really strong gusts. I couldn’t believe there wasn’t a tornado warning out. I got things secured on our deck and immediately I thought, “Oh s**t, the hopyard!”

It can be frustrating being 2+ hours away from your Farm, but such is life at the moment. I went to bed knowing even if I was there, there was nothing I could do about it. Each day, four times a day, my brother and I get an image from the hopyard from the trailcam. The first arrives at 6am, which even with the light sensitive camera, it can be hard to make out. I saw it, something looked off, but I didn’t think anything about it and back to work at the computer I went. And then I saw the one at noon. “Oh s**t!” was right.

I’m studying the picture and it took me only a few seconds, after the shock wore off, to realize what happened – a pole hadn’t blown over, it snapped in half! The pole, or what was left of it, was standing upright and I could see the coir, bines, and cabling were all still intact. The way we wire our poles together, luckily even in a failure like this, it isolated the issue and it appeared all was not lost.

I shot off a text to my brothers Mike and Devin who live in town. Typically one of them makes a trip out during the day to visit the folks. If it’s Devin, he takes Norris their dog, for a quick walk as well, up past the small hopyard. That day he hadn’t and I knew Mike hadn’t been out there yet. So I sweated it for a few hours until Mike got there and Facetime’d me from the field. Confirmation…snapped in half!

I couldn’t get up there until Friday evening after work wrapped up. Wouldn’t matter anyway, I knew I needed a full day for us to get a new pole in place. Luckily when we put in the large yard, we had a couple extra poles left over. This was the first time we had to dip into our stash.

I got up early Saturday morning after assessing the situation Friday evening when I got up to Saint Marys. First order of business – fire up the IH, attach the bucket loader, add on the pallet forks, bring the heavy chains, and the cant hook to help roll the pole I’d need. My original thought was I’d drag out the new pole from the woods, and scoop it up onto the pallet forks. However, these are black locust poles and if you’re not familiar with them, they are dense as all get out and heavy as hell. I quickly realized trying to balance a 24′ pole on the forks all the way down to the small yard would’ve been comical at best.

Out came the chains, secured it to the 3 point hitch, and slowly across a quarter mile of open field we went. Not an issue. That was step one. The next step would be to get the remainder of the old pole out of the hole, then clear and widen that hole to make ready for the new pole. This was a great opportunity to try the old Farmer trick of removing posts – a solid tire used as a fulcrum, good heavy chains, and a little luck. You place the tire right at the base of the pole, run the chains from the tractor up over the tire and secure it tightly down low at the base of the pole. Thanks to Physics, it pulls the pole out of the hole with much less resistance. Huzzah!

Up to this point, it was all seeming a bit too easy, meaning nothing broke yet and I hadn’t injured myself – the typical gauge I use 😉 Step three had a degree of squirrelliness that could achieve both in one step however. I might be able to at the very least damage the tractor or even flip it (we still don’t have a ROPS yet) and in either situation, it was definite I could bring some injury upon myself. I will say I’m much more cautious than I used to be at a younger age, however there’s always that clock ticking in the back of my head. Too much to do, never enough time to do it. This was not how I’d planned out the work day for Saturday earlier that week.

The choice was either to try and pick up the pole vertically with the bucket and fork and drop it into the hole, or shove the base into the hole while scooting it across the ground, and then raise it into place hoping it dropped down fully into the hole. The first option wasn’t really an option, just a pipe dream (pole dream?). Considering the pole is 24′ tall and thousands of pounds, the angles it’d be working at would flip the tractor like a top. I chose option number two, and although there was still the possibility of flipping the tractor, I had more control over the timing and it’d be easier to ditch the plan if something went awry.

In the end, option two worked quite well. It stands about 6″ taller than the other poles as it’s hard to get the poles all the way in that way, but our end poles are guyed-out in four directions so I was ok with the result. Now came the “fun” part…getting the cables with hundreds of pounds of hops bines on them, secured and in place on the new pole. It was at this point in mid-afternoon brother Mike was able to get out to help. We began the slow, methodical process of disconnecting each of the three cables, and then one often the other using the come along, havens grip, and one of my old climbing ropes to get them rigged.

The primary issue, second to our safety of course, was making sure we didn’t damage the bines. At this point in the season, the base of the bines are quite thick, like the thickness of your thumb. So as long as we didn’t bend them too much or pull the line too tight and uproot them, we should be good. The first two lines went pretty smoothly. The last one (of course) took a little more head scratching than the others. Long story short, all was secured and back in place by 7pm, which left me just enough time and daylight to spray our first batch of kaolin clay to start hopefully ridding the yard of the Japanese beetle infestation we were experiencing…THE worst we’ve seen to date. More on that in a later post.

And that my friends is the story of our first snapped pole. It won’t be the last we’re certain, but it did help emphasize to us that we needed to evaluate the remainder of the other poles and make plans after the season to swap out a few of those as well before Winter sets in.

Such is life at a hop Farm 🙂